“M2X keeps drivers informed. For example, they might have to turn left because it’s too dangerous to turn right. Or, there is a bridge ahead and if you turn right onto it, you’ll get stuck because there’s not a wide enough turning circle. Issues are avoided because all that information is digitally available and it doesn’t rely on institutional knowledge,” says Senja.

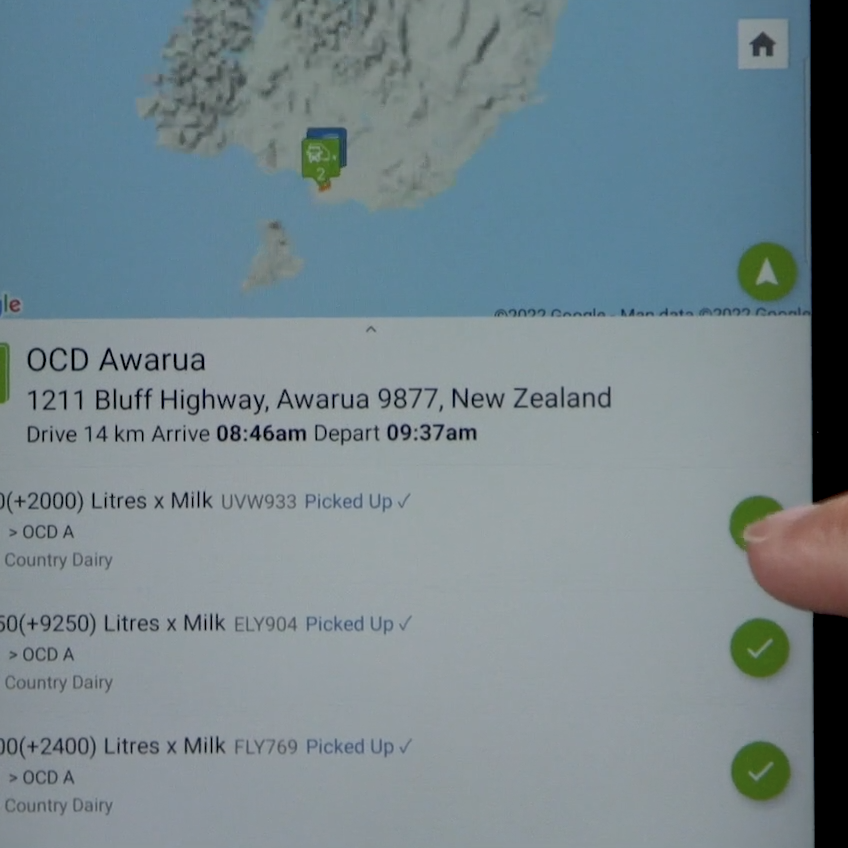

The cloud-based system is operated from computers at Open Country’s head office, which feature a map view of the region’s tanker routes and farms. Open Country’s tanker drivers use either an iPad or download the app on their phone, which they refer to before getting on the road.

“It has all the smarts behind the scenes,” says Senja. “It’s highly sophisticated technology but it’s actually very simple to use. That’s the way it needs to be if we want people to pick it up and run with it.”

The system also recognises High Productivity Motor Vehicle (HPMV) routes which allow trucks weighing more than 45 tonnes to travel on them.

This allows Open Country dispatchers to assess if an HPMV truck has capacity to pick up milk and if the farm’s pick-up location is on one of the specially designated HPMV routes.

“Because dispatchers have a map view, they can see where the trucks are and if there’s a truck passing a farm that has capacity to take additional load,” says Senja. “It allows them to make quick decisions based on real time milk volumes and events.”

Improved Communications & Logistics

Alongside creating greater transparency and efficiency across Open Country’s transport operations, the technology has also halved the time spent forecasting and planning and boosted the volume of milk moved.

Open Country Logistics Improvement Coordinator Jess Greenwood says moving to a digital platform was a big change and it was originally quite daunting for many of his team.

The app was initially launched to 120 drivers last year. During the transition period, a more manual backup system was put in place for them if they had any issues. But Open Country’s drivers embraced the change, and the feedback has all been positive.

“We have recently started using the M2X platform’s optimising tool, which schedules all our collections for us and from there we just need to dispatch them. This has cut our scheduling workload in half,” says Jess.

The platform has improved Open Country’s communication with its tanker drivers. They can send and receive real-time updates and make on-the-day changes if issues like unforeseen emergencies on specific farms crop up.

M2X also provides Open Country with valuable insights for decision making based on data about milk volumes, fleet use and kilometres travelled.

Now the app is launched, Open Country’s partnership with M2X doesn’t stop there! The two companies will continue to work together, make improvements, and build on the wins they have had to date.